We do

HMI Group is a global sourcing provider with own facilities in Munich, Milwakee, Sydney Shenzhen, Suzhou, Taipei

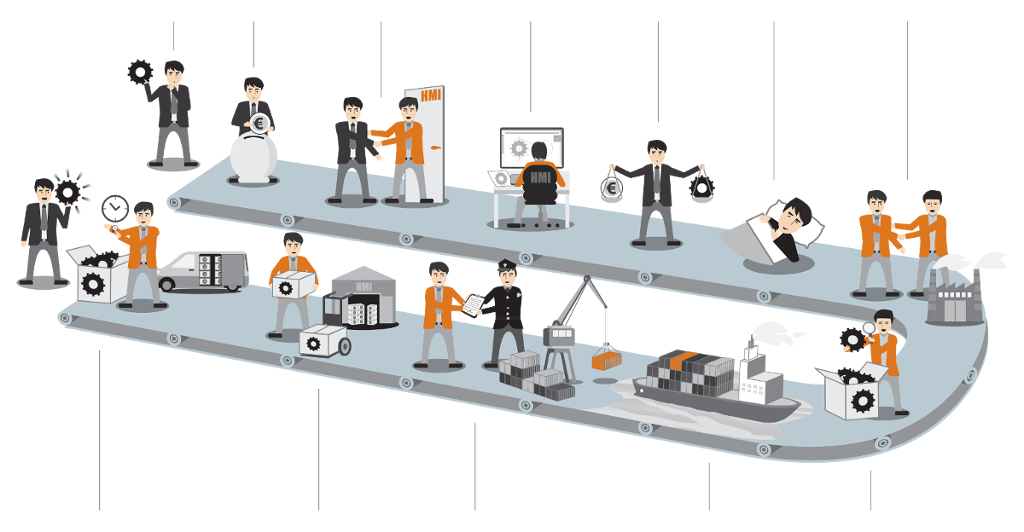

RFQ Management and Quotations

Once a factory or group of factories has been qualified, the RFQ process can continue with confidence.

more...

On-Site Engineering Support

When your project requires tooling fixtures or dies of any kind to be developed, HMI Group …

Factory Identification and Evaluation

So now you’re looking for someone to make your product. Some questions to consider …

Production and Schedule Monitoring

HMI Group will ensure that your product stays on schedule and ships when you need it. Once the production process …

more...

Contract Assembly

Located in our Suzhou, PRC plant location, HMI Group has the ability to assemble your products …

more...

Quality Assurance and Final Inspection

High quality does not happen by accident. Any project that relies upon Quality being “inspected in” …

more...

Worldwide Logistics Support

Your goods are ready to ship from the factory. Now what? Just relax and let HMI Group take care of the shipping …

Total Supply Chain Inventory Management

Are you looking for a way to increase efficiency and reduce costs through reduction of on-hand inventory, …

more...

Promotional items

Whether it is a simple logo application or an entire custom OEM object, HMI can support you in the development …

more...The Crew.

We believe in a diverse range of personel to bring creative skills,

thoughts and ideas to the table.

Michael Ratte

CEO

Munich EU

Attilio Barzaghi

Operations

Munich EU

Arnold Grimm

Sales Assistance

Munich EU

Paul Chang

Operation Manager

Shenzhen China

Eric Hsu

Procurement

Taipei Taiwan

Melissa Ma

Logistics

Suzhou China

Richard Huang

Senior Engineer

Taipei Taiwan

Tony Xu

Senior Engineer

Shenzhen China

Beth Duehr

Business Development

Milwaukee USA

Brian Chartier

Vice President – Sales

Milwaukee USA

Dave Duehr

CEO/CFO

Milwaukee USA

Alan Broeckling

Sales Manager

Milwaukee USA

James Zhang

Import/Export

Sydney Australia

June Severs

Back Office

Sydney Australia

Paul Bird

Operations

Sydney Australia

Wayne Dowie

Business Development

Sydney Australia

HMI sourcing system workflow

*Graphic representation of full service capabilities. Payments and steps of activities depends on specific case commercial agreements and industrial production constraints.

Solutions

HMI Group listens to your needs and designs sourcing programs that meet your requirements. We focus …

Glocal

Bringing quality and value closer to home: since 1985, HMI GROUP has simplified the process of bringing …

more...Sourcing

When you work with HMI Group to source and supply your products, the benefits will be seen right…

Manufacturing

HMI Group is a supplier of both OEM and aftermarket components and systems and has experience…

more...manufacturing facilities

warehouses

offices

containers shipped every year

Processes

HMI capabilities covers a vast array of industrial production process. For more details on this please get in touch with our engineers, we will be happy to share with you thirty years’ experience in product industrialization

Our expertise include: cut & bending, casting, assembled devices, extrusion, forging, molding, powder sintering, stamping, general assembly and off the shelf products customization of commodity products.

Casting with additional processing and finishings

Precision casting, lost wax casting, investment casting parts. By aluminum, zama, and various alloys. HMI offer is particularly competitive when further machining and/or coating is added on top.

Assembled electromechanical devices

Simple electromechanical devices including wiring, basic pcb circuits, injection molded housings, assembling and testing

Custom wiring

Wiring is a very labor intense product and requires skilled manual work, therefore very appropriate for Asian production

Subssemblies ready for your production line

HMI can deliver to customer subassemblies ready to be used in final production line, or to be applied by on site customer installers (eg.: sanitay accessories)

Manual metalwork

Cut and bend welded parts by carbon steel, stainless steel or aluminium. Including CNC re-working, any necessary welding fixture, chroming or powder-coating finishing.

Extrusion with finishing

Extruded profiles with further processing such as chopping, CNC machining and anodising

Assembled components

HMI has wide experience in the production of chrome and polished assemblies for the motorbike industry such as rear view mirrors, footrests, triple trees.

Assembled sanitary components

Valve assemblies, water taps, design syphons, towel holders, adjustable mirrors, just like assembly kits including tools and instructions ready to be used in construction site.

CNC machined parts

Casted / machined parts in brass, aluminium, steel, gray iron, POM, ABS etc..

Custom LED devices

Customized LED devices for specific use, developed under customer supervision based on customer own property owner design.

CNC assemblies

Machined and assembled parts including functional testing and on site industrialization tune up.

Sand casting

Large sand castings for structural use in construction industry, including production traceability, geometrical, mechanical and chemical inspection.

Tooling development

Casting, molding, extrusion, forging, stamping tooling development. Including fixtures and testing gauges up to customer sample approval. HMI reputation relies on the guarantee we bring customer to technical approval.

Forging

Forged parts for structural use in automotive or building industry. By hard steel or alloys. Including detailed deburring, machining and final finishing.

Cut bend weld metalworks

Cut and bend light metalwork including manual welding brazing and preparation for further processing such as painting polishing or brushing

Assembled locks

Complete lock assemblies with flexibility of family configuration and codification based on customer proprietary design

OEM glass bottles

Glass products based on customer specific artistic design

R&D to production

Co-design development of customer ideas in to concepts, engineering, cost-to -production realistic analysis, prototyping, sampling and serial production.

Casting and machining assemblies

Valve assemblies, water taps, design syphons, towel holders, adjustable mirrors, just like assembly kits including tools and instructions ready to be used in construction site.

Metalpressing

Competitive metal pressing tooling to be combined with further processing such as welding assembling coating

Metal synthering

Metal sintering for precision mechanical parts such as gears and small components

Injection moulding

Competitive injection moulding tooling for plastic and rubber to be combined with further assembly steps

Coating and finishing

Design finishing for the furniture business as well as technical coatings for protective use in construction or automotive application, to be applied on any previous processing.

Special finishings

Gears, racks, special threads, in combination with many processing systems

Dave Duehr

BOD member and founder

Michael Ratte

BOD member and founder

Peter Chworowsky

BOD member and founder

Russell L. Hitchcock

BOD member and founder